9 Common Metal Fabrication Processes Explained

Metal fabrication is the process of transforming raw metal materials into finished structures or components through methods that shape, join, and modify the metal. It is a critical part of manufacturing and construction, producing everything from structural frames and machinery parts to everyday items, including appliances and tools.

Metal fabrication shops typically house a variety of industrial machines to employ different metal fabrication methods, each with its own distinct applications for a durable, functional product. This blog aims to explore the most common metal fabrication processes, offering engineers and manufacturers an in-depth understanding of each technique.

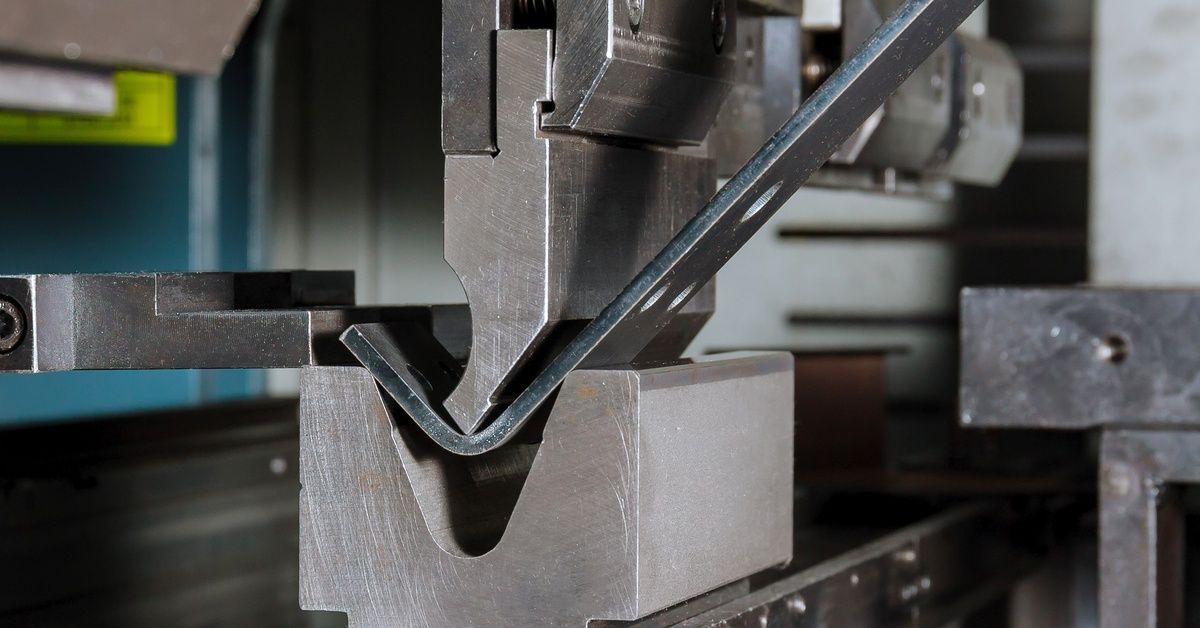

Bending

Bending is a fundamental metal fabrication process applies force to shape metal into a desired angle or curvature, typically using a press brake or other specialized machinery. This step typically follows other cutting or shaping processes on a sheet or solid metal piece.

The material is plastically deformed without compromising its integrity, creating precise, angular folds. However, bending has limitations for certain materials, like those that are too brittle or possess low ductility, as they may crack or break during the process.

Casting

Casting is one of the oldest, most versatile metal fabrication methods that’s used extensively for creating complex shapes. It involves pouring molten metal into a mold, where it cools and solidifies into the desired form. Metals such as aluminum, steel, iron, and bronze are commonly cast for various applications, including automotive parts, industrial machinery, and household appliances.

This process is ideal for manufacturing components with intricate geometries that would be difficult or impossible to achieve through other methods. Additionally, casting provides ease of replication and scalability, making it a versatile solution for large-scale production.

Cutting

Cutting is a critical process in metal fabrication, as it involves dividing metal into specified shapes or sizes, laying the foundation for further processing. There are several cutting techniques employed to accommodate different materials and precision levels.

Manual tools, such as saws and shears, support basic cutting tasks. Advanced methods like laser cutting, plasma cutting, and waterjet cutting provide superior precision and clean edges.

Folding

Folding is a specialized technique used to bend metal into a specific shape along a straight axis. This differs from conventional bending processes in terms of the approach and complexity they accommodate.

Precision is key to ensuring the folds meet dimensional accuracy and design intent. The process employs dedicated press brakes, clamping the metal workpiece before applying force along the bend axis. This process is ideal for creating smaller, more intricate components required in structural assemblies and industrial applications.

Machining

Machining removes excess material from a metal workpiece to achieve precise dimensions and surface finishes. It employs tools like drills for creating holes, lathes for shaping cylindrical objects, and mills for cutting and shaping complex surfaces, depending on the complexity and requirements of the project.

Computer numerical control (CNC) machining enables exceptional precision and consistency by automating the machining process. The method is advantageous for creating intricate components with high tolerances from various materials, including aluminum, steel, and copper. Precise machining not only enhances functionality but also minimizes material waste, an important factor in cost control.

Punching

Punching is a metal fabrication process that creates precise holes or cut-outs in a sheet of metal by applying force to a punch, which pushes the material through a matching die underneath. This technique is widely used for fabricating structural connections, attaching fasteners, or creating intricate aesthetic patterns.

Depending on the project, users can perform punching on metal sheets or thick materials using hydraulic or mechanical punch presses. Accuracy is essential to guarantee that the punched holes align with design specifications, particularly in projects requiring multiple components to fit together seamlessly.

Shearing

Shearing is a cutting process commonly used to make precise, straight cuts in metal sheets or plates. This efficient method employs a sharp blade or set of blades to sever the metal into large, uniform pieces while minimizing distortion or unevenness along the cut edge.

Shearing is frequently utilized in manufacturing and fabrication when creating parts for structural frameworks, industrial machinery, or other applications requiring clean, straight edges. The process’s efficiency makes it particularly useful for preparing materials for further fabrication steps. The accuracy of the process ensures compatibility with tightly specified dimensions, allowing components to fit seamlessly in complex assemblies or systems.

Stamping

Stamping is a high-speed process where a press shapes or embosses metal into the user’s desired design. Unlike punching techniques, stamping does not cut or penetrate a sheet of metal. Instead, specialized tools, like hydraulic presses, use stamps to imprint designs such as letters, numbers, or other graphics into a flat material.

This fabrication method offers precision and uniformity, making it an efficient choice for large-scale production while maintaining cost-effectiveness. Working with a reputable metal fabrication shop and establishing a clear line of communication is crucial for meeting specific design requirements.

Welding

Welding is one of the most common and versatile techniques for joining metal pieces. It uses heat and pressure to fuse materials, creating a permanent bond with mechanical strength. There are several types of welding processes regularly employed in metal fabrication, including MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding.

MIG welding, for instance, is ideal for fast and efficient joining of thicker materials, while TIG welding provides precise control for intricate designs and thinner metals. From assembling structural frameworks to repairing machinery, welding provides a reliable performance across numerous applications.

The Essential Role of Metal Fabrication in Manufacturing

Metal fabrication enables businesses to create components and structures fundamental to various industries. From precision machining for aerospace components to efficient cutting techniques for automotive production, these processes ensure functionality, quality, and reliability for the products we use in everyday life. By understanding the applications and benefits of metal fabrication processes, engineers and manufacturers can select the correct methods according to their project specifications.

James Manufacturing is a trusted name for metal fabrication in the Dallas-Fort Worth area. We’re known for our timely, friendly communication and transparent pricing. Contact us to discuss your project needs and how we can offer personalized solutions for satisfying results.