Ways CNC Machining Benefits the Electronics Industry

From smartphones to laptops, electronics are integral to our daily lives. But have you ever wondered how these devices are manufactured with such precision and efficiency? Enter CNC machining, a game-changer in the electronics sector. Explore the many ways CNC machining benefits the electronics industry.

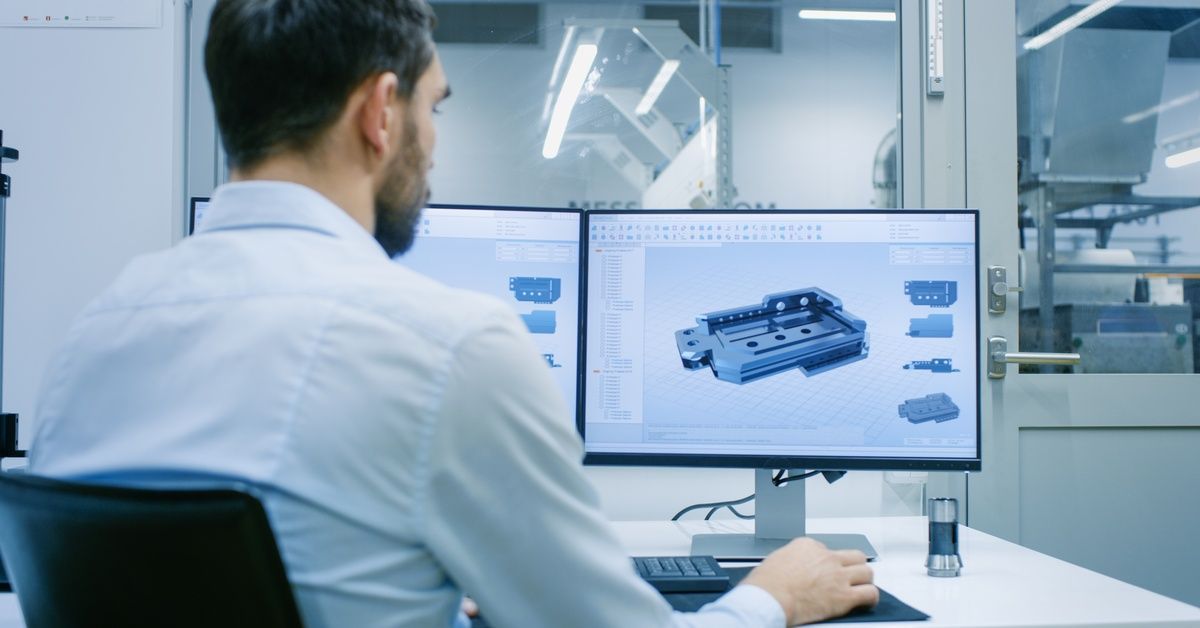

The Role of CNC Machining in the Electronics Industry

CNC machining plays a pivotal role in the electronics industry by enabling the production of highly precise and complex components. This technology uses computer-controlled tools and machinery to shape and fabricate electronic parts from various materials, including metals and plastics.

There are many advantages to this approach, making it easier than ever for companies to design, prototype, and build new and innovative electronic components.

Better Control Over Designs

One of the primary advantages of CNC machining is its ability to achieve exact specifications with minimal deviation, which is essential for producing intricate components used in devices like circuit boards and connectors.

Accelerated Testing Periods

CNC machining supports rapid prototyping, allowing manufacturers to test and refine designs quickly before moving to mass production. This flexibility not only accelerates the development process but also reduces costs associated with design adjustments and material waste.

Fewer Mistakes in the Final Product

The automation inherent in CNC systems reduces the potential for human error, leading to higher consistency and repeatability in manufacturing. This level of precision is crucial when dealing with the minuscule components found in modern electronic devices.

The Evolution of CNC Machining in Electronics Manufacturing

The evolution of CNC machining has been marked by significant advancements in technology and capabilities. Initially, CNC machines were limited to basic tasks, but over the years, they have evolved to handle more complex and precise operations.

Increased Automation and Integration

One of the key developments in CNC machining is the increased automation and integration with other advanced technologies. CNC systems now often include sophisticated software and sensors that enhance machine monitoring and control. This integration allows for real-time adjustments and quality monitoring, leading to more efficient production processes and reduced downtime.

Advancements in Materials and Tooling

Another significant improvement pertains to the materials and tooling used in CNC machining. With advancements in materials science, machinists are now able to work with a wider range of materials, including advanced composites and lightweight alloys. Enhanced tooling options have also emerged, providing greater precision and adaptability during the manufacturing process and allowing for more intricate and reliable electronic components.

Enhanced Precision and Accuracy

Enhanced precision and accuracy have become hallmarks of modern CNC machining. The development of high-speed, high-precision machines has enabled manufacturers to produce smaller, more complex components with near-perfect results. These advancements are crucial in the production of miniaturized electronics, such as microchips and sensors, which demand extremely tight tolerances.

The Rise of Eco-friendly Manufacturing

Sustainability has gained prominence, leading to CNC machining innovations that focus on eco-friendly manufacturing. Energy-efficient machines and processes have emerged, reducing environmental impact while maintaining production goals. This shift toward sustainable practices helps electronics manufacturers minimize waste and optimize resource usage, aligning with the broader industry move toward greener technologies.

Products That Benefit From CNC Machining

CNC machining is integral to the production of various electronic components, from circuit boards to connectors. Many everyday electronic devices rely on CNC-machined parts to function effectively, showcasing the versatility and importance of this technology in modern manufacturing. Some of the devices that benefit from CNC processes include:

- Smartphones: Precision CNC machining is essential in crafting components such as the casings, connectors, and circuit board frameworks that form the basis of modern smartphones.

- Laptops: From creating intricate hinges to making the durable yet lightweight chassis, CNC machining enables the fabrication of vital laptop components that meet exact design specifications.

- Wearable devices: Devices like smartwatches and fitness trackers rely on CNC-machined parts for durability and precision, including custom-fit casings and sensor enclosures.

- Drones: CNC machining is utilized to produce the lightweight frames and critical internal parts necessary for the balance and stability of drones.

- Medical devices: High-precision CNC machining is crucial in the creation of medical electronics, producing components like surgical instruments and diagnostic equipment housings.

- Automotive electronics: Advanced automotive systems, including GPS units and onboard computers, benefit from CNC-machined components for reliability and performance.

- Telecommunication equipment: The production of routers, servers, and other telecommunication devices often involves CNC machining to ensure precision and quality.

Future Trends and Innovations in CNC Machining for Electronics

The future of CNC machining in the electronics industry looks promising, with ongoing innovations set to enhance its capabilities further.

Increased Integration With AI and Machine Learning

The future of CNC machining in the electronics industry will increasingly involve the integration of AI and machine learning. These technologies will enable machines to learn from production data, improving decision-making and enhancing process efficiencies. This level of integration will allow for predictive maintenance and real-time optimization, leading to even greater precision and productivity in manufacturing.

Enhanced Customization and Personalization

As consumer demands continue to evolve, CNC machining will play a crucial part in enabling mass customization and personalization of electronics. Future systems are expected to offer more flexibility, allowing for custom designs and specialized configurations tailored to individual needs.

Adoption of 5G and IoT Technologies

The rise of 5G and IoT will drive the need for more sophisticated electronic components, pushing CNC machining technology to further adapt. This trend will likely lead to the development of new machining techniques and approaches that cater to the production of smaller, more complex parts required for connected devices.

Advancements in Hybrid Manufacturing Techniques

The integration of CNC machining with other manufacturing technologies, such as additive manufacturing (3D printing), will become more prevalent. These hybrid approaches will capitalize on the precision and flexibility of both technologies, enabling the production of complex electronic components quickly and cost-effectively.

Greater Emphasis on Sustainability

Future trends will see CNC machining become more environmentally conscious, with increased emphasis on sustainable practices. This will involve the adoption of eco-friendly materials, energy-efficient machines, and closed-loop systems that minimize waste and reduce carbon footprints, aligning with the growing demand for sustainable production practices across industries.

The Impact of CNC Machining in Electronics

CNC machining has transformed the electronics industry, offering unparalleled precision, consistency, and efficiency in manufacturing. Its numerous advantages make it an essential tool for modern electronics manufacturers. By recognizing these important ways CNC machining benefits the electronics industry, businesses can produce high-quality electronic products that meet the demands of today’s consumers.

For those in the electronics industry, exploring CNC machining is a crucial step toward achieving greater efficiency and innovation. If you’re looking to partner with a CNC machining shop you can trust, contact our team at James Manufacturing. We offer a range of services that will help your electronics manufacturing business thrive in an increasingly competitive market.